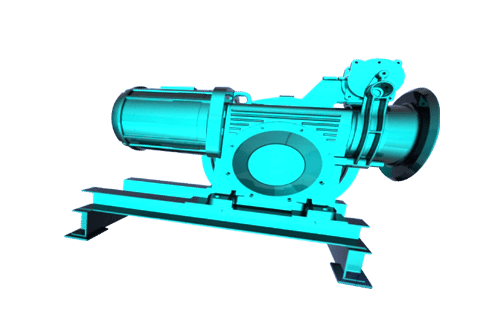

Electric Gear Box

8000 INR/Unit

Product Details:

X

Electric Gear Box Price And Quantity

- 8000 INR/Unit

- 1 Unit

Electric Gear Box Trade Information

- 5 Unit Per Day

- 1 Week

- Wooden Box.

- All India

Product Description

An electric gearbox, also known as an electric motor gearbox, is a type of gearbox that is specifically designed to work in conjunction with an electric motor. It is used in various applications where precise control of speed and torque is required, such as in robotics, automation, and electric vehicles.

Electric gearboxes can be categorized into several types based on their construction and design. Some of the most common types of electric gearboxes include inline, parallel, and right-angle gearboxes. Inline gearboxes are designed to transmit power between parallel shafts and are commonly used in applications that require high torque and low speed. Parallel gearboxes are used to transmit power between two parallel shafts and are commonly used in conveyor systems and material handling equipment. Right-angle gearboxes are used to transmit power between two intersecting shafts and are commonly used in electric vehicles, wind turbines, and robotics.

Electric gearboxes are designed to work seamlessly with electric motors, providing the required speed reduction and torque multiplication needed for various applications. They are generally more efficient and quieter than traditional gearboxes, as they do not rely on a mechanical system to operate. Proper selection and maintenance of an electric gearbox is important for optimal performance, efficiency, and to avoid downtime due to gearbox failure.

When selecting an electric gearbox, it is important to consider factors such as the torque and power requirements of the application, the speed and direction of the shafts, and the type of load being applied. Proper lubrication and maintenance of the gearbox is also important for optimal performance and longevity.

Enter Buying Requirement Details

Other Products in 'Pbl Gear Box' category

"We are only dealing in North India."

Call Me Free

Call Me Free