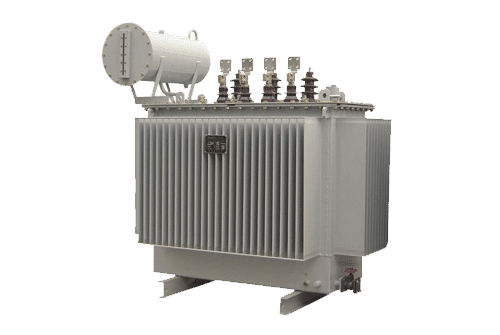

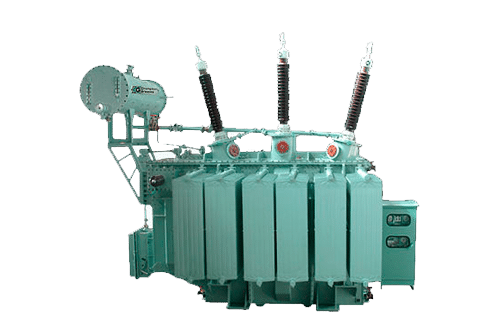

Kirloskar Distribution Transformer

250000 INR/Unit

Product Details:

- Rated Voltage 220 Volt (V)

- Low Voltage 380 Volt (V)

- High Voltage 5 Volt (V)

- Capacity 5000 Kg/hr

- Material Copper and Steel

- Frequency (MHz) 50 Hertz (HZ)

- Weight 500-800 Kilograms (kg)

- Click to view more

X

Kirloskar Distribution Transformer Price And Quantity

- 250000 INR/Unit

- 1 Unit

Kirloskar Distribution Transformer Product Specifications

- 220 Volt (V)

- 500-800 Kilograms (kg)

- 50 Hertz (HZ)

- 5 Volt (V)

- 380 Volt (V)

- Copper and Steel

- 5000 Kg/hr

Kirloskar Distribution Transformer Trade Information

- 5 Unit Per Day

- 1 Week

- Wooden Box.

- All India

Product Description

Kirloskar Electric is a leading manufacturer of distribution transformers, which are electrical devices used to step down high voltage power to a lower voltage level for local distribution. Distribution transformers are essential components in electrical power distribution systems and are used to transfer electrical energy from one circuit to another.

Kirloskar distribution transformers are designed to meet the specific needs of various industries, including power generation, transmission, and distribution. They are available in different types, sizes, and configurations, each designed for specific applications. Some of the common types of Kirloskar distribution transformers include single-phase distribution transformers, three-phase distribution transformers, and pad-mounted distribution transformers.

Single-phase distribution transformers are used in low voltage distribution networks and are designed for small-scale applications, such as in residential areas. Three-phase distribution transformers are used in high voltage distribution networks and are designed for industrial and commercial applications. Pad-mounted distribution transformers are designed to be installed in outdoor environments and are commonly used in underground electrical systems.

Kirloskar distribution transformers are designed to be efficient, reliable, and durable. They are manufactured using high-quality materials and are tested to ensure that they meet international quality standards. Proper installation, operation, and maintenance of Kirloskar distribution transformers is important for optimal performance and longevity.

When selecting a Kirloskar distribution transformer, it is important to consider factors such as the voltage and current requirements of the application, the type of load being supplied, and the environmental conditions in which the transformer will be installed. Proper installation and maintenance of the transformer, including regular testing and monitoring, is essential for optimal performance and to avoid downtime due to transformer failure.

Enter Buying Requirement Details

Other Products in 'Kirloskar Transformers' category

"We are only dealing in North India."

Call Me Free

Call Me Free